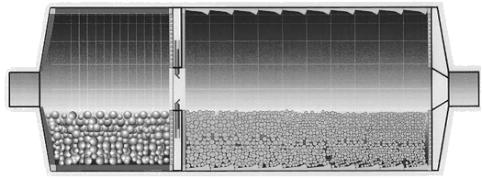

High Quality Grinding Media Ball - Ball Mill High Chromium Alloy Casted Grinding Ball – EASFUN

High Quality Grinding Media Ball - Ball Mill High Chromium Alloy Casted Grinding Ball – EASFUN Detail:

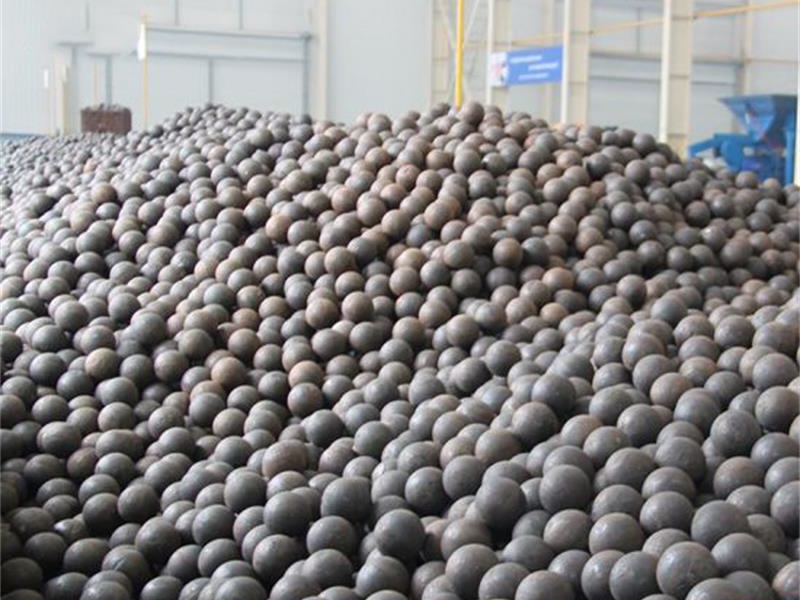

Diameter:φ15-120mm

Application: It is widely used in various mines, cement plants, power plants and chemical industries.

Chromium forged balls are widely used in powder preparation, and ultra-fine powdering of cement, metal ores and coal slurries. They are used in thermal power, chemical engineering, ceramic paint, light industry, papermaking and magnetic material industries, besides others. Forged grinding balls have excellent toughness, preserve their circular shape, low wear and tear, and a low crushing rate. The hardness of our high chromium ball product is 56–62 HRC, the hardness of medium chromium ball is up to 47–55 HRC, while the hardness of the low chromium ball is up to 45–52 HRC, with 15 mm as the minimum and 120 mm as the maximum diameter. It is widely used in a variety of dry mills.

Material: Low chromium alloy

C: 2.2-3.5 % Si: 0.5-1.5 % Mn: 0.3-1.5 % Cr: 1.0-3.0 % S: ≦0.060 %

Material: Medium chromium alloy

C: 2.2-3.2 % Si: 0.5-1.5 % Mn: 0.3-1.5 % Cr: 5.0-7.0 % S: ≦0.060 %

Material: High chromium alloy

C: 2.2-3.2 % Si: <1.2 % Mn: 0.3-1.5 % Cr: 10-13 % S: ≦0.060 %

Material: Extra high chromium alloy

C: 2.0-3.0 % Si: 0.5-1.5 % Mn: 0.3-1.5 % Cr: 17-19 % S: ≦0.060 %

1. Pre-shipment- SGS inspection at the factory/harbor prior the dispatch (Strictly NO scrap metal/bars or other steel qualities used in manufacturing).

2. Grinding balls to be packed in steel drums with openable top (with threads) or Bulk bags.

3. Drums packed on pallets made of heat treated wood or plywood, two drums per pallet.

Bags: Our grinding media can be supplied in UV resistant polypropylene (PP) bags. Our bulk bags are also equipped with lifting straps to allow easy loading and unloading.

Drums: Our grinding media can also be supplied in sealed recycled drums strapped to wooden pallets.

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for High Quality Grinding Media Ball - Ball Mill High Chromium Alloy Casted Grinding Ball – EASFUN, The product will supply to all over the world, such as: Tajikistan, Iran, Macedonia, Really should any of these items be of interest to you, please let us know. We will be pleased to give you a quotation upon receipt of one's detailed specifications. We've our personal specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.